Portable CMM Laser Scanning

Non-contact 3D laser scanners provide fast and accurate data compared to tactile CMMs when the article in question contains inorganic or broad shapes such as a scribe line fixture. Our portable CMM laser scanners also have direct advantages for large objects and our ability to come to your location.

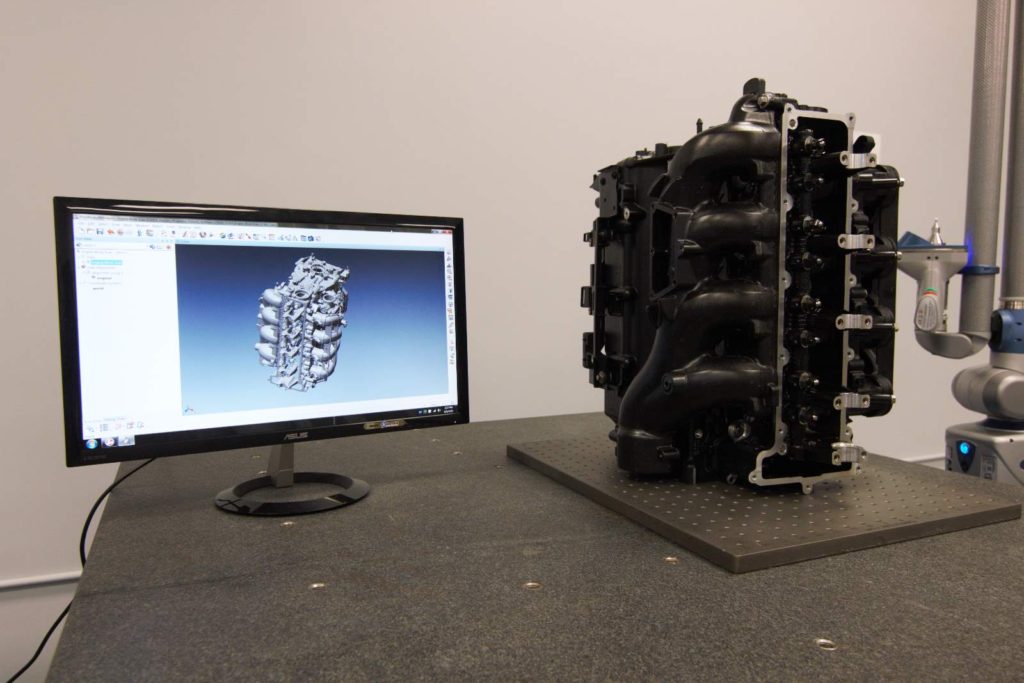

Carolina Metrology uses multiple Faro portable arm CMMs with a laser for 3D measurement and inspection. Being portable, the Faro arm allows for 3D laser scanning at our dimensional inspection lab or on-site at your location- even on your shop floor. On-site 3D inspection avoids the inconvenience of shipping out large parts or fixtures and can provide quick feedback for calibrations and adjustments.

Our engineers use PolyWorks as the software of choice for our 3D laser scanners. PolyWorks makes everything from dimensional inspection to point cloud analysis and reverse engineering possible without the need to change software for each application. Some typical applications for 3D Laser scanning include:

Common 3D Laser Scanner Uses:

- Complex 3D parts

- Certification of fixtures

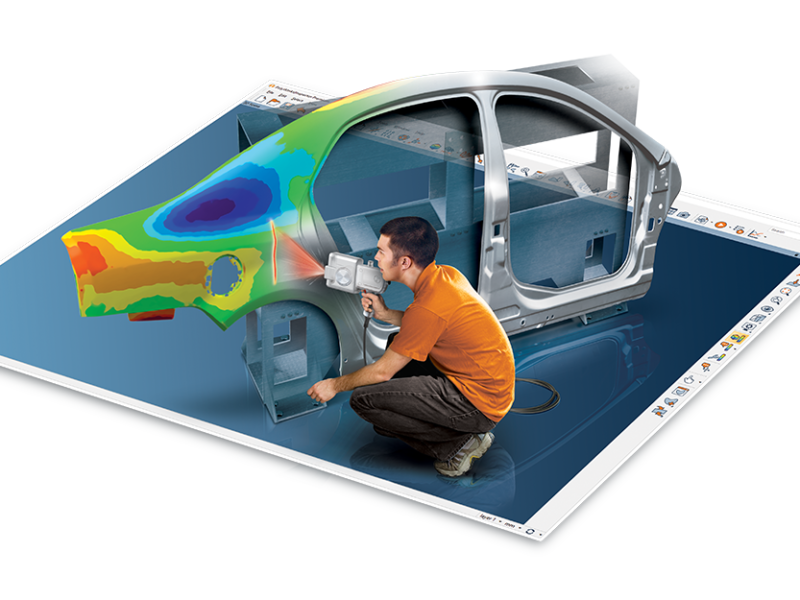

- Gap and flush verification

- Part to CAD analysis

- Reverse engineering

About 3D Laser Scanning for Dimensional Analysis

3D Laser Scanning is a non-contact method to gather large amounts of point data from an object using a line of laser light. The points gathered can then be utilized in a number of ways, the most common being color mapping of deviation of a real object to a CAD model.

3D Laser scanners are also used in reverse engineering to create a CAD model from a real object. Depending on the 3D laser scanner configuration, scanned objects scanned can be micrometers small or larger than a jumbo jet.