Gage Repeatability and Reproducibility

If you need a gage R&R study completed, you’ve come to the right place. Carolina Metrology has extensive knowledge in providing quality on-site and in-lab gage repeatability and reproducibility studies. We use a variety of standardized forms including the AIAG short and long-form templates.

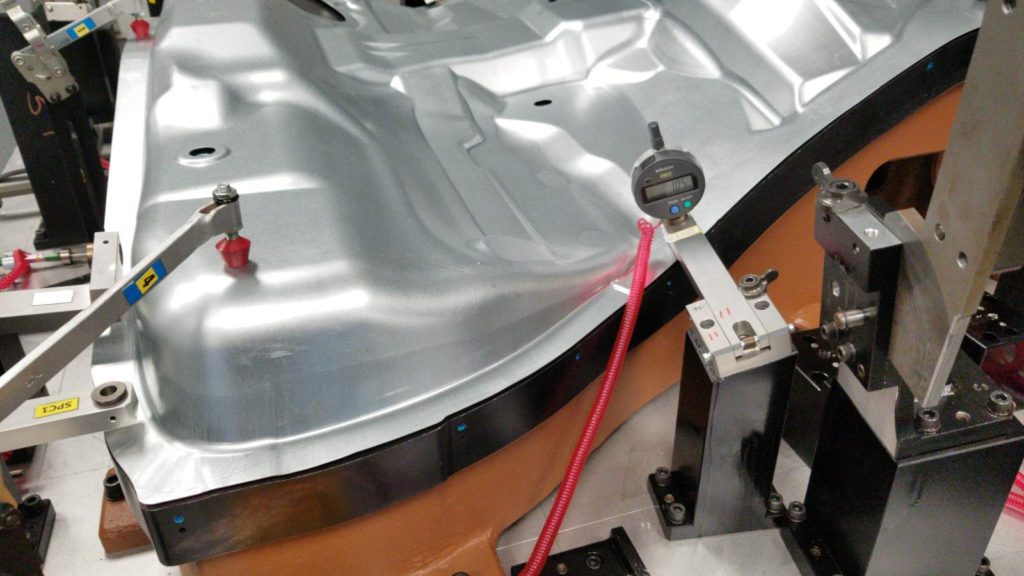

Gage R&R studies are all about being done precisely from the clamping procedures to proper data entry. Using industry-standard templates, we can account for part variability, operator variability, and gage variability to ensure your fixture is in good working order. Failure to account for these variables can result in good check fixtures failing or a bad test gage passing.

Gage R&R Training

Carolina Metrology provides both speed and accuracy in the R&R process. We can provide operator training to improve the usage of your current fleet of check fixtures to ensure accurate data collection to track your process variability. Our engineers often uncover gage enhancement opportunities as well as ideal clamping procedures which substantially increase the value of gages for our customers. We can manage an R&R study with your operators or expedite the process with our experienced team.

Gauge R&R Study Capabilities:

- AIAG short and long-form

- On-Site Studies to avoid shipping fees and damage

- Short lead times for completions

- CMM or Articulated Arm studies for Fixtures without SPC Ports

- Repair of non-repeatable fixture designs